Quality control is a cornerstone of organizational success, ensuring products meet specifications and standards. Roles like inspectors and technicians monitor production, conduct audits, and maintain compliance, while a Quality Control Roles and Responsibilities PDF guide provides clarity on duties, fostering efficiency and accountability across industries.

1.1. Importance of Quality Control in Organizations

Quality control is vital for ensuring products meet specifications and standards, reducing defects, and enhancing customer satisfaction. It fosters compliance with industry regulations, minimizes waste, and improves operational efficiency. By implementing robust quality control measures, organizations can maintain consistency, build brand reputation, and gain competitive advantages. Effective quality control also supports continuous improvement, enabling businesses to adapt to changing demands and deliver high-quality outputs consistently. Its importance lies in safeguarding organizational integrity, ensuring reliability, and driving long-term success across industries.

1.2. Overview of Key Roles in Quality Control

Quality control involves a variety of roles, each contributing to ensuring high standards. Key roles include Quality Control Managers, who oversee processes and compliance, and Quality Control Inspectors, who conduct audits and tests. Quality Control Technicians support technical aspects, while Quality Control Auditors evaluate systems for adherence to regulations. Additionally, Quality Control Specialists focus on specific areas like documentation and risk mitigation. These roles collectively ensure that products meet quality benchmarks, maintaining customer satisfaction and organizational integrity. Their collaboration is essential for achieving operational excellence and regulatory compliance across industries.

1.3. Purpose of a Quality Control Roles and Responsibilities PDF

A Quality Control Roles and Responsibilities PDF serves as a comprehensive guide, clarifying the duties of various quality control positions. It outlines the tasks, expectations, and standards for roles like inspectors, technicians, and managers; This document ensures alignment with industry regulations and organizational goals, providing a clear framework for implementing quality control processes. By detailing key responsibilities, it aids in training, compliance, and accountability, ultimately enhancing operational efficiency and product quality. It is an essential tool for maintaining consistency and excellence across industries, making it a vital resource for both new and experienced professionals.

Primary Quality Control Roles

Primary quality control roles include Quality Control Managers, Inspectors, Technicians, Auditors, and Specialists. These roles ensure compliance, conduct inspections, monitor processes, and maintain high standards across industries.

2.1. Quality Control Manager

The Quality Control Manager oversees all quality assurance activities, implementing processes to ensure compliance with industry standards. They supervise teams, develop quality metrics, and identify risks. Their role involves managing audits, calibrating equipment, and maintaining documentation. They also collaborate with other departments to improve production efficiency and product reliability; Effective managers possess strong leadership and analytical skills, ensuring that quality objectives are met consistently. Their responsibilities are crucial for maintaining customer satisfaction and organizational reputation.

2.2. Quality Control Inspector

A Quality Control Inspector is responsible for ensuring products meet quality and safety standards. They conduct thorough inspections, analyze measurements, and perform tests to identify defects. Inspectors maintain detailed records of findings and report issues to management. Their role involves monitoring production processes, verifying compliance with specifications, and supporting corrective actions. Proficiency in using inspection tools and understanding GMP guidelines is essential. Inspectors play a vital role in maintaining product quality, reducing defects, and ensuring customer satisfaction. Their attention to detail and analytical skills are critical in upholding organizational standards.

2.3. Quality Control Technician

A Quality Control Technician supports quality assurance processes by conducting tests, calibrating equipment, and analyzing data. They ensure compliance with GMP guidelines and maintain accurate records. Technicians assist in identifying defects, monitoring production, and implementing corrective actions. Their role requires strong technical skills, attention to detail, and the ability to follow detailed procedures. They work closely with other quality control roles to ensure high standards are met, contributing to overall product quality and organizational efficiency. Their tasks are essential for maintaining consistency and reliability in final outputs.

2.4. Quality Control Auditor

A Quality Control Auditor evaluates processes to ensure compliance with industry standards and internal policies. They conduct audits, review documentation, and assess system effectiveness. Auditors identify non-compliance issues and recommend improvements. Their role involves verifying calibration records, maintenance activities, and testing procedures. They ensure that all quality control measures are consistently applied, fostering a culture of accountability. By identifying risks and ensuring adherence to regulations, auditors play a crucial role in maintaining product integrity and organizational credibility. Their findings help organizations improve their quality management systems and achieve operational excellence.

2.5. Quality Control Specialist

A Quality Control Specialist is a multifaceted role focused on ensuring high standards of quality across products and processes. Key responsibilities include conducting tests, analyzing data, and identifying defects or inconsistencies. They collaborate with production and engineering teams to address quality issues promptly. Specialists also document findings, maintain detailed records, and ensure compliance with industry regulations. Their work is critical in maintaining customer satisfaction and organizational reputation. Additionally, they may assist in process improvement initiatives and support audits to enhance overall quality management systems.

Key Responsibilities of Quality Control Roles

Quality control roles involve ensuring compliance with specifications, conducting regular inspections, monitoring production processes, identifying risks, and maintaining accurate documentation to uphold quality standards across organizations.

3.1. Ensuring Compliance with Specifications

Ensuring compliance involves verifying that products meet established standards, regulations, and customer requirements. Quality control teams conduct meticulous inspections, testing, and documentation reviews to confirm adherence. This step is critical for maintaining product quality, safety, and customer satisfaction. By adhering to specifications, organizations minimize risks, avoid recalls, and build trust. Compliance checks are integrated throughout production, from raw materials to finished goods, ensuring consistency and reliability.

3.2. Conducting Regular Inspections and Audits

Regular inspections and audits are essential for maintaining quality standards. These activities involve evaluating products, processes, and systems to identify defects or non-compliance. Inspectors and auditors assess materials, monitor production steps, and verify adherence to specifications. By conducting these checks, organizations ensure consistency, reduce errors, and improve overall product quality. Audits also help identify areas for improvement, fostering a culture of continuous enhancement. Detailed reports and documentation from these activities provide actionable insights, enabling timely corrections and ensuring customer satisfaction.

3.3. Monitoring Production Processes

Monitoring production processes is a critical aspect of quality control, ensuring that all stages of production adhere to predefined standards. This involves observing workflows, testing materials, and analyzing outputs to detect deviations. By continuously overseeing production, quality control teams can identify and address issues promptly, minimizing defects and ensuring consistency. Effective monitoring also helps optimize efficiency, reduce waste, and maintain compliance with industry regulations. Regular checks and real-time data analysis are key tools in this process, enabling organizations to deliver high-quality products while maintaining operational excellence and customer satisfaction.

3.4. Identifying and Mitigating Risks

Identifying and mitigating risks is a vital function of quality control, ensuring potential threats to product quality are addressed proactively. Teams analyze processes to pinpoint vulnerabilities, such as equipment malfunctions or material inconsistencies. By implementing preventive measures like enhanced inspections or process adjustments, risks are minimized. Effective risk management not only safeguards product integrity but also prevents costly rework and enhances customer trust. Regular assessments and adaptive strategies are essential to stay ahead of emerging challenges and maintain high standards of quality across all operations.

3.5. Maintaining Documentation and Records

Maintaining accurate and comprehensive documentation is a cornerstone of quality control. Detailed records of inspections, audits, and test results ensure compliance with industry standards and provide traceability. Proper documentation also supports continuous improvement by identifying trends and areas for optimization. From raw material verification to final product testing, every step must be meticulously recorded. This not only aids in regulatory compliance but also enhances transparency and accountability within the organization. Effective record-keeping is essential for audits and serves as a valuable resource for future reference and decision-making processes.

Quality Control in Specific Industries

Quality control roles vary across industries, with manufacturing, construction, pharmaceuticals, and food safety requiring tailored approaches. Each sector has unique standards, ensuring safety, compliance, and product integrity.

4.1. Quality Control Roles in Manufacturing

In manufacturing, quality control roles ensure products meet specifications and standards. Inspectors conduct regular checks, while technicians monitor production processes. Managers oversee compliance with GMP guidelines, calibrate equipment, and maintain records. These roles are crucial for detecting defects, ensuring timely delivery, and upholding customer satisfaction. By implementing quality control measures, manufacturing units minimize risks, optimize workflows, and adhere to industry regulations, ensuring the final products are safe and reliable for consumers. Effective quality control in manufacturing is essential for maintaining brand reputation and operational efficiency.

4.2. Quality Control Roles in Construction

In construction, quality control roles focus on ensuring compliance with project specifications and industry standards. Supervisors oversee construction work to verify adherence to quality benchmarks, while managers establish and monitor QC activities. Key responsibilities include documenting procedures, managing records, and mitigating risks. These roles ensure that materials and processes meet required standards, reducing defects and enhancing safety. Effective quality control in construction is vital for delivering projects on time, within budget, and to the satisfaction of clients. It also helps in maintaining regulatory compliance and upholding the integrity of the built environment.

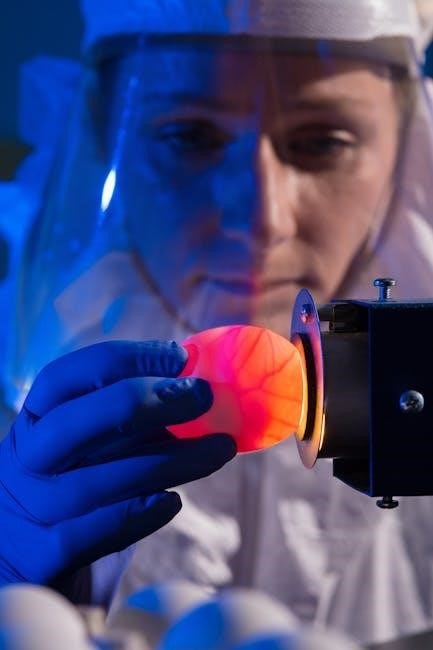

4.3. Quality Control Roles in the Pharmaceutical Industry

In the pharmaceutical industry, quality control roles are critical to ensuring drug safety and efficacy. Responsibilities include testing products, monitoring production processes, and maintaining compliance with GMP guidelines. Quality control technicians calibrate equipment, validate processes, and review records to ensure accuracy. They also support audits and inspections, ensuring adherence to regulatory standards. Effective documentation and traceability are key, as they help in identifying and addressing potential issues promptly. These roles are essential for maintaining public trust and ensuring that pharmaceutical products meet stringent quality and safety requirements before reaching the market.

4.4. Quality Control Roles in Food Safety

In food safety, quality control roles ensure compliance with industry standards and regulations. Inspectors conduct regular audits, monitor production processes, and test products to prevent contamination. Technicians maintain accurate records and documentation, while specialists focus on risk management and continuous improvement. These roles are vital for safeguarding consumer health and maintaining brand reputation. By implementing robust quality control measures, organizations in the food industry can minimize risks, ensure product integrity, and comply with legal requirements, ultimately contributing to a safer food supply chain and customer trust.

Skills and Qualifications for Quality Control Roles

Quality control roles require technical skills, attention to detail, and certifications. Strong communication and problem-solving abilities ensure effective compliance and continuous improvement in processes.

5.1. Necessary Technical Skills

Necessary technical skills for quality control roles include expertise in statistical process control, calibration, and quality management systems. Proficiency in using tools like SPC and TQM methodologies is essential. Knowledge of GMP guidelines and experience with analytical equipment calibration is also critical. Familiarity with quality control software and automation tools enhances efficiency. These skills enable professionals to monitor production processes effectively, identify defects, and ensure compliance with industry standards, ultimately contributing to the delivery of high-quality products and services.

5.2. Required Education and Certifications

Quality control roles typically require a bachelor’s degree in engineering, science, or a related field. Certifications like Lean Six Sigma, ISO standards, or GMP compliance enhance credibility. Professional certifications such as Certified Quality Manager (CQM) or Certified Quality Technician (CQT) demonstrate expertise. Specific industries may require additional certifications, such as food safety or pharmaceutical standards. Staying updated with industry-specific certifications ensures adherence to evolving regulatory requirements and enhances career advancement opportunities in quality control.

5.3. Soft Skills for Effective Quality Control

Essential soft skills for quality control roles include attention to detail, strong analytical thinking, and excellent communication. Teamwork and collaboration are critical, as quality control often involves cross-functional efforts. Problem-solving skills are vital for identifying and addressing defects. Adaptability is key to handling changing processes and standards. Leadership qualities help inspire others to prioritize quality. Time management ensures tasks are completed efficiently, while accountability fosters trust and reliability. These skills, combined with technical expertise, enable individuals to excel in quality control and drive organizational success.

Tools and Techniques Used in Quality Control

Statistical Process Control (SPC), Total Quality Management (TQM), and Lean Six Sigma methodologies are key tools. Quality control software and automation tools enhance efficiency and accuracy in monitoring processes.

6.1. Statistical Process Control (SPC)

Statistical Process Control (SPC) is a method used to monitor and control processes through statistical methods. It involves real-time data collection to detect deviations in processes, ensuring consistency and reducing variability. SPC helps identify trends, predict issues, and prevent defects, enabling proactive corrections. By setting control limits, it distinguishes between natural variability and special causes of variation. This technique is widely used in manufacturing and other industries to maintain quality standards, improve efficiency, and reduce waste. SPC is a cornerstone of modern quality control, enhancing operational precision and customer satisfaction.

6.2. Total Quality Management (TQM)

Total Quality Management (TQM) is a holistic approach to quality control that integrates all organizational functions to achieve customer satisfaction. It emphasizes continuous improvement, employee involvement, and data-driven decision-making. TQM fosters a culture of excellence by aligning processes with strategic goals. Key principles include customer focus, process-centered approaches, and continuous learning. By engaging all employees, TQM ensures that quality is built into every stage of production. This methodology reduces errors, enhances efficiency, and promotes sustainable improvement, making it a vital tool for organizations aiming to deliver superior products and services while maintaining long-term success.

6.3. Lean Six Sigma Methodologies

Lean Six Sigma combines Lean principles and Six Sigma tools to optimize processes, reduce waste, and enhance quality. It focuses on identifying and eliminating defects through data-driven approaches. The DMAIC (Define, Measure, Analyze, Improve, Control) methodology is central to Lean Six Sigma, enabling systematic problem-solving. Professionals certified as Green Belts or Black Belts lead initiatives, fostering a culture of continuous improvement. By integrating Lean’s efficiency with Six Sigma’s rigor, organizations achieve higher customer satisfaction, reduced variability, and improved profitability, making it a powerful framework for quality control roles in driving operational excellence and sustainable growth.

6.4. Quality Control Software and Automation Tools

Quality control software and automation tools streamline processes, enhance accuracy, and reduce human error. These tools enable real-time monitoring, data collection, and analysis, ensuring compliance with industry standards. Automated systems can generate detailed reports, track defects, and manage corrective actions. Software solutions like SPC and TQM platforms support continuous improvement, while automation tools optimize testing and inspection workflows. By integrating these technologies, organizations improve efficiency, maintain consistent quality, and ensure regulatory compliance, ultimately driving operational excellence and customer satisfaction in various industries.

Best Practices for Implementing Quality Control

Implementing quality control involves continuous improvement, employee training, and clear communication. Regular audits, performance reviews, and employee engagement ensure sustained quality and alignment with organizational goals.

7.1. Continuous Improvement Strategies

Continuous improvement strategies are essential for sustaining quality control. Regular process reviews, feedback loops, and lean methodologies help identify inefficiencies. Encouraging employee suggestions fosters a culture of ongoing refinement. By integrating tools like Statistical Process Control (SPC) and Lean Six Sigma, organizations can systematically enhance operations. Training programs and performance metrics further support these efforts, ensuring that improvements are measurable and aligned with organizational goals. This proactive approach not only elevates product quality but also drives long-term business success.

7.2. Employee Training and Awareness

Employee training and awareness are critical for effective quality control. Regular training sessions ensure staff understand quality standards and procedures. Updated knowledge on industry regulations and tools like TQM and Six Sigma enhances compliance. Practical exercises and workshops foster hands-on learning, reducing errors. Awareness campaigns promote a culture of quality, encouraging employees to identify and report defects. Continuous learning opportunities empower teams to adapt to new challenges, ensuring sustained quality improvement and accountability across all levels of the organization.

7.3. Effective Communication Channels

Effective communication channels are essential for seamless quality control processes. Clear and timely reporting ensures issues are addressed promptly. Regular meetings and feedback loops foster collaboration between teams. Documentation of findings and corrective actions maintains transparency. Utilizing tools like SPC and TQM helps streamline information flow. Open lines of communication between management, inspectors, and technicians ensure alignment with quality goals. Standardized reporting formats and accessible platforms further enhance efficiency. Clear communication minimizes misunderstandings, enabling teams to focus on continuous improvement and compliance with industry standards. This promotes a culture of accountability and shared responsibility for quality outcomes.

7.4. Regular Performance Reviews

Regular performance reviews are crucial for evaluating the effectiveness of quality control processes. These reviews help identify strengths and areas needing improvement. By aligning reviews with quality goals, organizations ensure accountability and consistency. Performance metrics, such as defect rates and compliance adherence, are analyzed to assess progress. Feedback from inspections and audits is incorporated to refine strategies. Continuous improvement initiatives are prioritized based on review outcomes. Documentation of findings and action plans ensures transparency and follow-up. Regular reviews foster a culture of accountability, driving teams to achieve higher standards and maintain operational excellence in quality control roles.

Documentation and Reporting in Quality Control

Documentation and reporting are vital for maintaining quality control standards. Accurate records ensure compliance, traceability, and continuous improvement in quality processes and outcomes.

8.1. Types of Quality Control Reports

Quality control reports include audit reports, inspection reports, and compliance reports. These documents track product quality, identify defects, and ensure adherence to industry standards. Audit reports evaluate the effectiveness of quality systems, while inspection reports detail product testing results. Compliance reports verify that processes meet regulatory requirements. Additionally, performance metrics reports analyze trends and improvements. Each type of report provides actionable insights, enabling organizations to address issues promptly and maintain high-quality outputs. Accurate and timely reporting is essential for transparency and accountability in quality control processes.

8.2. Importance of Accurate Record-Keeping

Accurate record-keeping is vital for maintaining compliance, traceability, and accountability in quality control processes. It ensures that all activities, inspections, and test results are documented thoroughly. Proper records facilitate audits, providing evidence of adherence to standards and regulations. They also support root cause analysis for defects and enable continuous improvement initiatives. Maintaining detailed calibration, validation, and maintenance records ensures equipment functionality and data integrity. Accurate documentation is essential for legal compliance, customer trust, and operational efficiency, making it a cornerstone of effective quality control systems.

8.3. Compliance with Industry Standards

Compliance with industry standards is critical for ensuring product safety, reliability, and market acceptance. Quality control roles must adhere to regulations like ISO, GMP, and FDA guidelines, depending on the industry. Accurate documentation and regular audits help verify compliance, maintaining trust and avoiding legal issues. Training employees on industry standards ensures consistency and reduces non-compliance risks. Compliance also enhances traceability, allowing for efficient recall processes if needed. By aligning with established standards, organizations ensure high-quality outputs and operational efficiency, fostering customer confidence and long-term success.

Challenges in Quality Control Roles

Managing tight deadlines, addressing non-compliance issues, and staying updated with industry changes are key challenges. These require adaptability, expertise, and proactive problem-solving to maintain quality standards effectively.

9.1. Managing Tight Deadlines

Quality control professionals often face the challenge of managing tight deadlines while ensuring compliance with standards. This requires efficient time management and prioritization of tasks. Deadlines may be imposed by production schedules, regulatory requirements, or client expectations. Missing deadlines can lead to delays in product delivery, increased costs, and potential non-compliance issues. To overcome this, quality control teams must streamline processes, leverage automation tools, and maintain clear communication with stakeholders. Effective planning and resource allocation are critical to meeting deadlines without compromising quality standards.

9.2. Dealing with Non-Compliance Issues

Non-compliance issues pose significant challenges in quality control, requiring immediate attention to prevent operational disruptions. Identifying root causes is critical to resolving these issues effectively. Consequences of non-compliance include legal penalties, reputational damage, and loss of customer trust. Quality control teams must implement corrective actions, such as process adjustments or additional training, to address deviations. Preventive measures, like enhanced inspections or updated protocols, help mitigate future risks. Effective communication and collaboration across departments are essential to ensure compliance and maintain high standards. Detailed documentation of issues and resolutions is also vital for accountability and continuous improvement.

9.3. Staying Updated with Industry Changes

Staying updated with industry changes is crucial for quality control professionals to maintain high standards and adapt to new regulations. Continuous learning through training programs, industry publications, and workshops ensures professionals stay informed. Leveraging technology and understanding regulatory updates are essential. Failing to stay updated can lead to compliance issues and inefficiencies. Fostering a culture of continuous learning is vital. Leadership should promote this culture, encouraging collaboration with experts and ensuring employees are informed and aligned with industry advancements to maintain quality, drive success, and foster innovation.

10.1. Summary of Key Points

10.2. The Future of Quality Control Roles

The future of quality control roles is poised for transformation, driven by advancements in automation, artificial intelligence, and data analytics. As industries evolve, the demand for skilled professionals who can adapt to new technologies will grow. Roles will focus more on predictive quality control, leveraging tools like AI and machine learning to identify potential issues before they arise. Additionally, sustainability and environmental standards will play a larger role, shaping the responsibilities of quality control teams. A Quality Control Roles and Responsibilities PDF will remain a vital resource, outlining the changing landscape and required competencies for future success.